COOL-PROTECT HI 6600-9343

COOL-PROTECT is a thixotropic 1K HYDRO Pigment filler with powerful filling properties and outstanding isolating characteristics relative to the contents of the wood. As an isolating primer under coloured finished, it reliably seals off the wood content and prevents bleeding into the colouring coat. It is also easy to apply on vertical surfaces and has good sanding properties. An ideal base for other HYDRO Pigment fillers or colour lacquers.

Enquire articlePage content

- 1C Isolating filler to counter discolouring wood ingredients

- for use on HEVEA and other "problematic woods"

- reliable protection on most woods, even with just one application.

- good sanding properties

- ideal isolation for combination with COOL-FILL

Processing

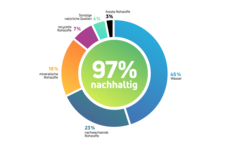

- water 46%

- mineral resources 23%

- fossil resources 31%

Areas of application

In the complete field of interior fittings for the living area on various types of wood: For furniture surfaces in the complete field of interior fittings: stairs, doors, ledges etc.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 0 % |

|---|---|

| Appearance | opaque |

| VOC EU % | 0,1 % |

| Number of layers (max) | 2 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 300 g/m² |

| Total quantity applied | 360 g/m² |

Processing Instructions

| Drying | 16 h / 20 °C |

|---|---|

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 120 - 400 |

| Intermediate sanding (grain size) | 280 - 400 |

| Yield per pass | m²/l |

| Processing information | COOL-PROTECT is usually applied 1 - 3 x with sufficient intermediate drying and optional intermediate sanding. Gentle sanding of the isolation filler is required prior to final coating with other lacquer systems. Caution: avoid sanding through!After application of COOL-PROTECT HI 6600-9343, it is important to thoroughly clean work tools, material hoses and lines. Otherwise the special formulation of COOL-PROTECT HI 6600-9343 can result in residues causing undesirable reactions with other HYDRO Lacquer systems. We recommend using HYDRO Cleaning agent HV 6917 to remove dried on lacquer remnants. Application devices should be flushed using HYDRO Reversing agent HV 6904 if both HYDRO and other solvent-based lacquers were used. |

| Special notes | Stir the material well before processing. This product is supplied ready-for-use and may be diluted with up to 5 % water if required.Resin seepage is natural and cannot be wholly prevented via technical coating measures, see BFS (German Federal Committee for Paints and Protective Coatings) Information sheet no. 18When used on woods which are particularly content-rich (such as poplar, Hevea brasiliensis, particular knotty pines, exotic woods, etc.), the number of isolating layers and the quality of the coating should be determined in advance on the original substrate.Experience shows that the first isolating layer activates the contents of the wood and embeds them in the lacquer layer. The second layer (or the third lacquer layer at most given extremely intensive wood contents) reliably isolates them and prevents any negative impact on the coloured top coat. “A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health or a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.