HYDRO Metalliclacquer HB 65445-(colour tone)

Strong thixotropic 1C HYDRO Metallic colour lacquer with good ability to stay on vertical surfaces and uniform effect formation. This light fast coloured lacquer is available in many colors and is particularly suitable for coating three-dimensional parts.

Enquire articlePage content

- even, non-cloudy effect formation

- the special flow characteristics prevent drips or sagging on vertical surfaces

- creates an exclusive metallic look

Processing

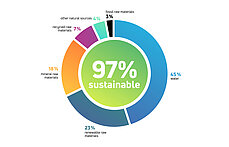

- water 73%

- mineral resources 3%

- fossil resources 24%

Areas of application

The material can be used universally as a metallic effect lacquer for closed-pore structures in living areas. Its thixotropic flow behaviour facilitates the coating of vertical surfaces. It can also be used for the direct coating of suitable, cleaned and sanded foils.

Technical information

General technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Number of layers (max) | 2 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 120 g/m² |

| Total quantity applied | 300 g/m² |

Processing Instructions

| Drying | 8 h / 20 °C |

|---|---|

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 120 - 400 |

| Intermediate sanding (grain size) | |

| Yield per pass | 9 m²/l |

| Processing information | When directly coating cleaned or sanded foils, please apply a test coat to check the bonding!.Clean tools with water. For removal of dried lacquer residues use Hesse HYDRO Cleaning agent HV 6917. In case of combined coatings (HYDRO- and solvent based lacquers) rinse application tools with Hesse HYDRO Reversing agent HV 6904. This product can be subjected to forced drying. Pre-priming is possible depending on the required finish and carrier material, for instance using: COOL-FILL HP 6645-9343, PERFECT-FILL HDP 5650-9343, FANTASTIC-FILL DP 4755-9343. |

| Special notes | The material is supplied ready to use and only needs to be diluted in exceptional cases. If needed, add a maximum of 5 % water or a maximum of 3 % HZ Optimizer 70. This addition significantly reduces the thixotropy. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.