PERFECT-NATURA bright HDE 54510

The light fast PERFECT-NATURA bright HDE 54510 can be used to achieve an open-pored, dull matt, scratch resistant and mechanically resilient surface with the natural look of wood. This topcoat is particularly interesting for sustainable objects, as it contains 11% renewable raw materials. Due to its pronounced brightening properties, PERFECT-NATURA bright is particularly suitable for use on light-colored wood types.

Enquire articlePage content

- natural wood effect (does not accentuate the grain picture) for light wood types

- dull matt look

- integrated light protection

- resource-saving, 11% renewable raw materials

- IMO-certified (requirements of the International Maritime Organization)

Processing

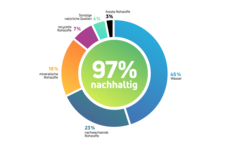

- water 64%

- renewable resources 11%

- mineral resources 1%

- fossil resources 24%

Areas of application

In the complete field of interior fittings for living areas as a natural wood effect; mainly on light-colored woods. Can also be used for stairs, Handrails and bleached Surfaces.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 11,37 % |

|---|---|

| Appearance | colourless |

| VOC EU % | 5,2 % |

| Number of layers (max) | 2 |

| Quantity per layers (min) | 80 g/m² |

| Quantity per layers (max) | 120 g/m² |

| Total quantity applied | 240 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: HDR 5091 |

| Mixing ratio (gravimetric) | 100 : 11 | Hardener: HDR 5091 |

Processing Instructions

| Potlife | 3 h / 20 °C |

|---|---|

| Drying | 3 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 120 - 220 |

| Intermediate sanding (grain size) | 280 - 320 |

| Yield per pass | 10 m²/l |

| Processing information | PERFECT-NATURA bright can be applied as a top coat, i.e. as a primer and as a top coat. Depending on the type of wood, the use of PERFECT-NATURA-BASE HDG 5410 is recommended to minimize wood discoloration. Add the hardener in a slow stream while stirring. If necessary, adjust the spray viscosity by adding water. Maximum addition rate 5 %. Hardener must always be added before thinning! Do not store material mixed with hardener in closed packaging. Overcoatability: possible with itself or suitable clear materials. Clean work tools with water. Use Hesse HYDRO Cleaner HV 6917 to remove dried lacquer residues. For combined work (water-based and solvent-based lacquers), rinse application equipment with Hesse HYDRO Rewetting agent HV 6904. |

| Special notes | Stir the lacquer material well! The product can be used on surfaces that have been bleached with hydrogen peroxide and thoroughly dried.We recommend using PERFECT-NATURA-BASE HDG 5410 in association with PERFECT-NATURA bright HDG 54510 (adding at most 5 % water) on tannin-rich woods with coarse pores, such as oak, to minimise wood discoloration and ensure effective pore wetting. Complete pore wetting substantially reduces the risk of impurities in the wood pores and facilitates surface care. The lightening effect is significantly dependent on the type of wood and its quality. Please therefore conduct a trial coating on the original bare wood in advance to check the result.Caution! Avoid sanding through the basecoat. There is a risk of blotching.This product is only permitted to be combined with other approved and technically suitable products if it is to be used as a low-flammable coating for seagoing vessels in accordance with SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, latest version, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when this product is used as a low-flammable coating for seagoing vessels is 160 g/m².“A risk assessment has been conducted in accordance with Directive 2014/90/EU, Annex II, Section 3. The hardened and dried coating poses neither a physical or health hazard nor a hazard to the environment.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.