Page content

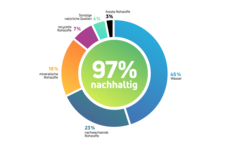

- water 61%

- mineral resources 2%

- fossil resources 37%

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.