PU Glass lacquer DE 4259x(gloss level)-0040

DE 4259x(gloss level)-0040 is a transparent, two-component, polyurethane acrylate resin glass lacquer that is characterised by its outstanding adhesion on glass, even on textured glass. The hardened surface is also highly resistant and light fast. This product can additionally be used as an adhesion agent between glass and other polyurethane lacquers.

Enquire articlePage content

- highly resistant surfaces

- outstanding adhesion on glass

Processing

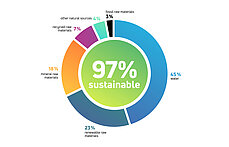

- water 1%

- renewable resources 1%

- mineral resources 2%

- fossil resources 96%

Areas of application

For all interior fixtures and fittings, including high demand areas such as kitchens and bathrooms.

Technical information

General technical information

Sustainability data sheet

Technical Specifications

| Appearance | colourless |

|---|---|

| Number of layers (max) | 3 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 450 g/m² |

| Mixing ratio (volumetric) | 5 : 1 | Hardener: DR 4076-0001 |

| Mixing ratio (gravimetric) | 100 : 22 | Hardener: DR 4076-0001 |

Processing Instructions

| Potlife | 8 h / 20 °C |

|---|---|

| Drying | 16 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | |

| Intermediate sanding (grain size) | |

| Yield per pass | 6 - 9 m²/l |

| Processing information | DE 4259x(gloss level)-00040 can be used to coat behind glass in critical wet areas like shower enclosures. |

| Special notes | The addition of 1 - 5 % Colour concentrate for solvent-containing lacquers CF or ZD 1-(colour tone) can be used to create glazed tinting. It should be noted in this regard that the lacquer application amount, the application method and the drying conditions influence the effect and colour tone of glass coatings. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.