It causes uncertainty

Even though the advantages of water-based lacquers are obvious, there is still some uncertainty among many processors of solvent-based coatings regarding the hazards of waterborne materials. It is often asserted that water-based lacquers are more harmful to health when inhaled and are more easily absorbed, or penetrate the skin when in contact.

Yet these concerns are unfounded. Especially when the guidelines relating to the processing and handling of lacquers are observed. These are the same for both lacquer systems (solvent-based and water-based) and largely exclude any health effects.

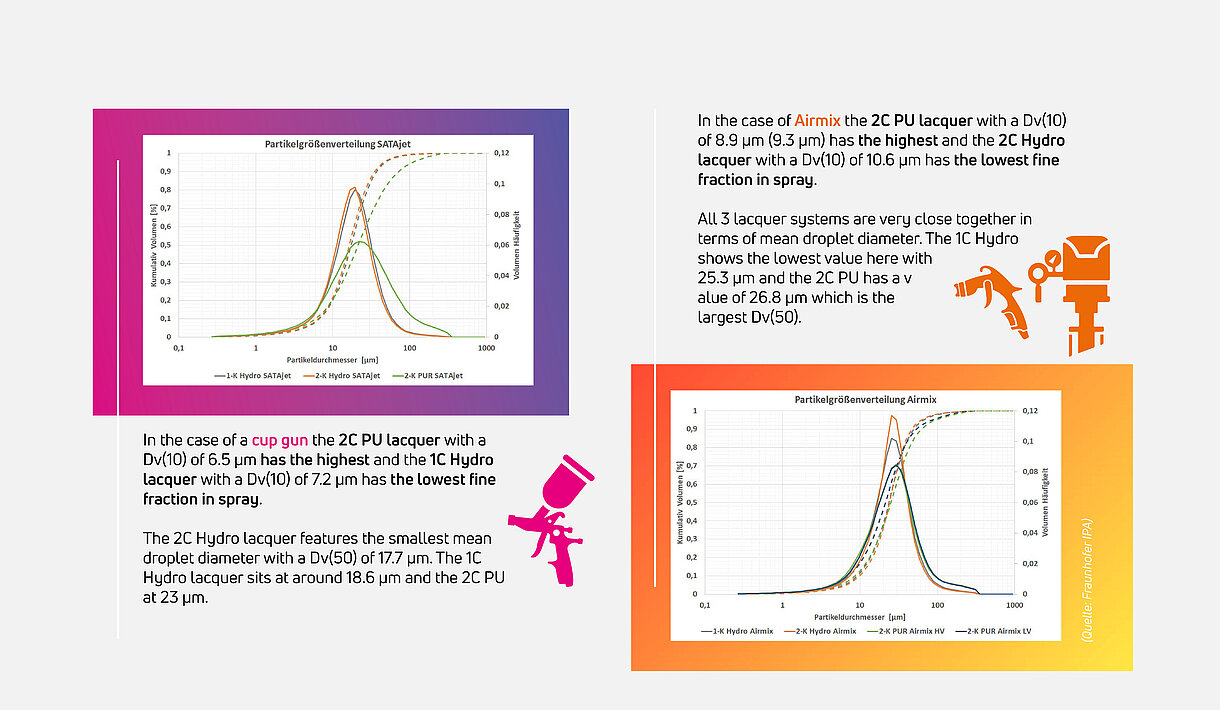

We also commissioned the Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer-Institut für Produktionstechnik und Automatisierung IPA) to conduct a scientific study comparing the particle size distribution during application via cup gun and via AirMix unit.

Experimental setup: In each case the study examined one version of

- typical 1C Hydro lacquers (such as COOL-TOP HE 6509x(gloss level)),

- genuine 2C Hydro lacquers (such as PERFECT-TOP HDE 5400x(gloss level), (mixing ratio: 10 : 1 with HDR 5091) and

- solvent-based 2C PU lacquers (such as: FANTASTIC-CLEAR DE 4877x(gloss level), (mixing ratio: 10 : 1 with DR 4071).

Here is a rough summary of the findings: