Fastest coating using lacquer or oil

Continuous optimisation for industrial parquet production

Laying parquet flooring in their own home is a real dream come true for many people. Industrial parquet manufacturers have for years been meeting the strong demand for this natural floor covering. It involves them using state-of-the-art production facilities and realising ever more efficient coatings.

UV lacquers for roller coating are generally used as a filler, basecoat and top lacquer to protect the surface. There is a choice of colouring stains, oils , or even cutting-edge excimer technology for dull matt surfaces.

Our product portfolio contains all the coating products required for the parquet industry.

Particularly eco-friendly producers rely on our Oxi-reactive oil for roller coating. It is sustainable, highly durable and at the same time enables the fastest cycles in production. From untreated wood to packaging usually takes less than six minutes. The highest quality demands regarding your products are simultaneously met.

Another benefit for you: the efficient production processes and perfect grammages can be documented and provided for your equipment operators. This ensures transparent communication and continuous quality assurance for all participants.

UV lacquer with biorenewable carbon

Increase the sustainability level of your products

Hesse Lignal is making the world a bit more sustainable with its BRC product series Better Carbon: these UV lacquers contain a high proportion of renewable raw materials and are therefore more eco-friendly than conventionally manufactured products. Better Carbon products are at the same time convincing due to their high level of durability and visually appealing results. Their lacquer formulations were developed in an elaborate process over several years and optimised to perfection. Non-BRC products can often without much effort be swapped for sustainable UV lacquers with a high BRC content. The Hesse Lignal team will be happy to provide advice if finishes need to be adjusted due to the use of other products or certain work procedures. Better Carbon can usually be combined with non-BRC products if it is not possible to swap products. There is no need to compromise on the quality of your finished products.

LEARN MORE

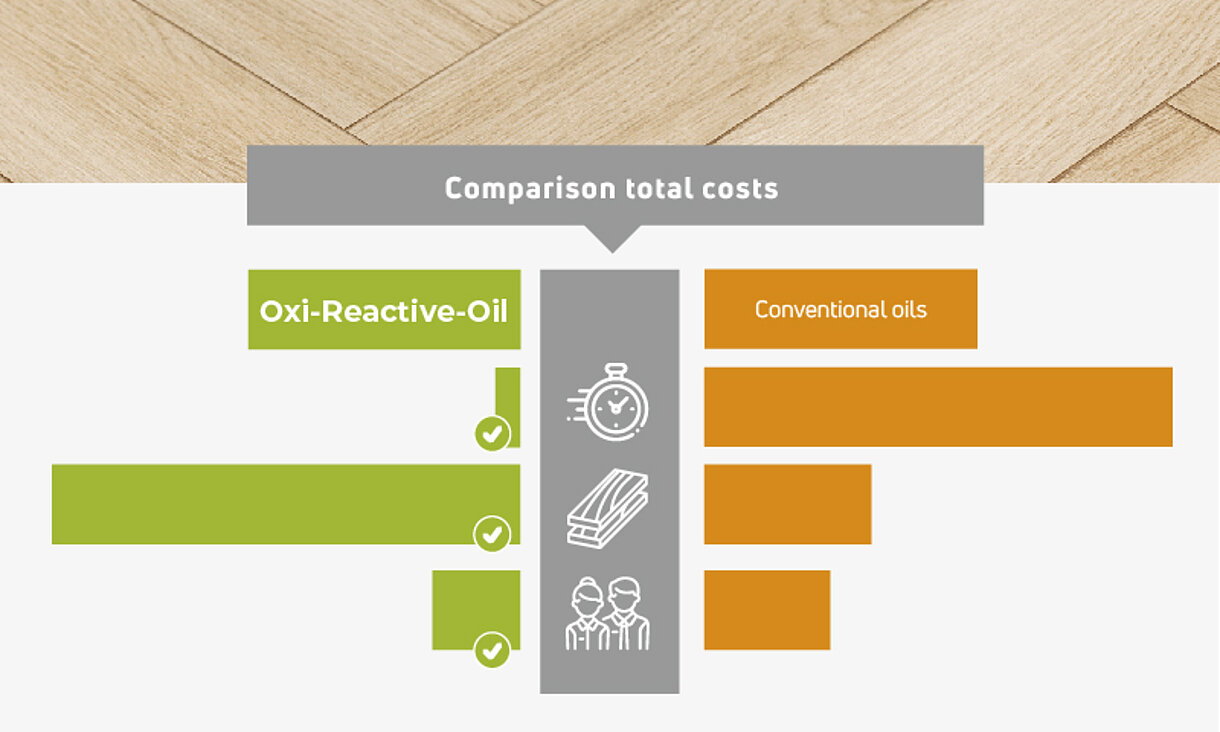

Conventional oils vs. Oxi-Reactive Oil

Cycle time 24 h vs. 6 min

Conventional oils vs. Oxi-Reactive Oil

Cycle time 24 h vs. 6 min

If you oil traditionally, in the best case you have a cycle time of 24 h. The biggest time wasters are the long drying times between oil applications and especially the length of time for complete drying prior to packaging.

The attractive alternative in terms of time is our Oxi-Reactive-Oil for Roller Coating. This gives you an average production time for multi-colour oil application of 10 min including packaging. Drying time is eliminated because UV activation takes place after each oil application and the surfaces therefore dry as quickly as possible.

All in all you save a vast amount of space, time and personnel resources!

Products for the parquet flooring industry

HARO - Hamberger

Convinced by competence and inspiration

HARO - Hamberger

Convinced by competence and inspiration

The HARO brand from Hamberger is a big name in the sector. It is only in the last few years that we’ve been supplying sustainable lacquers for very different product lines in various HARO facilities.

This customer praises not only our products, but especially their competent, inspiring collaboration with the entire Hesse team. That naturally makes us proud and very happy!

Decospan N. V.

Classic coating for industrial parquet flooring

Decospan N. V.

Classic coating for industrial parquet flooring

The company Decospan N. V. from Belgium is also an important customer of ours in this segment. Various floor programmes are coated there in a process-reliable manner using our stains as well as UV- and HYDRO-UV lacquers.

Long-term collaboration makes it important to repeatedly formulate specific objectives to ensure that the best result for each end product can be jointly determined. The best organisation is particularly important when it comes to exports. We ensure smooth functioning of both the supra-regional supply chain and the interaction between the customer, our local sales representatives and the departments involved at our production site in Hamm.

Contact person