PU PLANET-STONE basecoat clear DB 48900-0901

Our two-component PU PLANET-STONE Basic lacquer DB 48900-0901 is applied to a substrate and covered with one of the PLANET-STONE Powders. This creates a cover layer with real stone that is similar in visual effect, as well as mechanically, to solid stone. The choice of the PLANET-STONE stone powder, the colour of the substrate, the degree of sanding and the choice of top coat enable various effects to be achieved, from rough to polished stone with various degrees of gloss, from matt to high gloss.

PLANET-STONE offers a variety of benefits compared to real stone, both in terms of processing and maintenance. Coating materials in the most varied forms with a thin layer of real stone enable extremely diverse applications.

Hesse PLANET-STONE is also available in 1C and 2C HYDRO variants. For further information on this, please see the Technical Information: Hesse HYDRO PLANET-STONE Basic lacquer clear HE 65192 and HDM 54802-0901.

The stone powders are available in various colours and effects. Further information can be found in the "Accessories" section.

Enquire articlePage content

- real stone

- much lighter than solid stone

- sprayable

- durable

- complies with German Industrial Standard 68861-1B

Processing

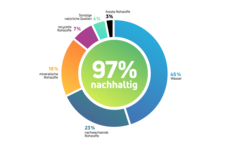

- water 1%

- renewable resources 1%

- mineral resources 1%

- fossil resources 97%

Areas of application

For all interior fittings and yacht building, tables and worktops, stairs and kitchen splashbacks.

Technical information

Sustainability data sheet

Technical Specifications

| Proportion of renewable raw materials % | 0,36 % |

|---|---|

| Appearance | colourless |

| VOC EU % | 75,8 % |

| Number of layers (max) | 3 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 450 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: DR 4071 |

| Mixing ratio (gravimetric) | 100 : 11 | Hardener: DR 4071 |

Processing Instructions

| Surface sanding (grain size) | 220 - 320 |

|---|---|

| Intermediate sanding (grain size) | |

| Yield per pass | m²/l |

| Processing information | Use two cup guns.Use one cup gun (with a normal 1.5 - 2 mm nozzle opening) to coat the surface to be treated with Hesse PLANET-STONE Basic lacquer.Fill the other cup gun (2.2 - 4 mm spray nozzle) with the selected PLANET-STONE Powder and spray the powder into the still moist Basic lacquer.After brief initial drying, cover the surface with a further layer of PLANET-STONE Basic lacquer.After hardening, the PLANET-STONE layer is coated within 24 h with one or more layers of FANTASTIC-CLEAR DE 4877x(gloss level), with sanding between layers to achieve a particular degree of smoothness/roughness. You can choose between a very rough up to a smooth, polished surface. The gloss level of the top coat naturally also contributes to the desired final effect.Reverse glass coating:PLANET-STONE can be applied on glass by adding 5 % EL 460-0025 to the PU PLANET-STONE Basic lacquer DB 48900-0901 hardening it with Hardener DR 4076-0001 at a ratio of 5 : 1. Then mix in PLANET-STONE Powder as described above and apply it to the well-cleaned glass.PLANET-STONE is a natural product and the colour tone may vary accordingly. Sufficient material for an object should therefore be ordered. With subsequent deliveries, differences in colour tone are possible. |

| Special notes | Preparation of the substrate and mixing and processing all basic lacquers and stone powders requires special knowledge. Our responsible sales representatives will be pleased to advise you. In addition to application by spraying, other methods of application are also possible. The application method you choose depends on the objects to be treated and the possibilities in situ. Our sales representatives can advise you on this too. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.