NATURAL-COLOR-OIL OB 5283x(gloss level)-(colour tone)

Hesse NATURAL-COLOR-OIL is a fast drying and low-odour mixture of natural oils and natural oils modified using alkyd resins; tinted with particularly light fast special pigments. Given the selection of exclusive raw materials, it is not subject to labelling under the current version of the GHS/CLP Regulation. It meets the requirements of EN 71-3 (11-2014) and is thus suitable for use on children’s toys. Once dried it forms a tough yet open-pore and breathable surface, which exhibits good abrasion resistance and good resistance against household chemicals. Apply 1 to 2 coats of the oil using a spatula, roller or cloth and rub it in. Then remove the excess.

Enquire articlePage content

- light fast special pigments

- good resistance against household chemicals

- fast-drying

- non-labelled according to GHS/CLP regulation

Processing

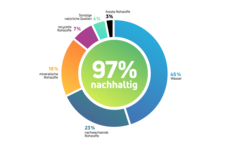

- renewable resources 12%

- mineral resources 33%

- fossil resources 55%

Areas of application

For use in creating coloured surfaces on indoor furniture, parquet flooring and staircase treads with normal to high use. Colour tone and effect plus chemical and mechanical resistance will depend on the number of oil coats applied.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | glazing |

|---|---|

| Number of layers (max) | 2 |

| Quantity per layers (min) | 10 g/m² |

| Quantity per layers (max) | 30 g/m² |

| Total quantity applied | 60 g/m² |

Processing Instructions

| Drying | 16 h / 20 °C |

|---|---|

| Due to hardening | 7 d / 20 °C |

| Surface sanding (grain size) | 120 - 180 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 35 - 105 m²/l |

| Processing information | Manual filling: Apply thinly with a trowel or roll on, then immediately pad in or rub in. Large areas should be coated by two people.Manual application: Rub in using a sanding fleece and remove any excess with a cotton cloth, leaving no residue. In the furniture sector: apply and rub in the product with a saturated fine sanding fleece. After a short exposure time, remove any excess with a cotton cloth. The surface should appear dry; if not, drying problems may occur. In special cases the material can also be thinly applied by spraying. Rubbing in and subsequent removal of the excess are as for manual application. The corresponding safety instructions for spray application must be followed! On parquet flooring: Apply the material with an appropriate trowel; after a short exposure time, work in evenly using the single-disc sander and white non-abrasive pad until the surface appears dry. |

| Special notes | You can lighten using OE 52832 or OE 52839. Products from the same range can be mixed with one another. The product is not suitable for woods susceptible to blue stain in damp rooms. The material properties were tested on commercially available woods such as oak, beech, etc. Please check suitability before using on other types of wood. In order to avoid white pores on dark, porous woods, we recommend using the glossy version of the oil, at least for the first coat. Hardening at 25 : 1 with OR 5180 increases the surface's mechanical and chemical resistance. The hardener additive accelerates complete drying. Pot life of the mixture at 1 h / 20 °C room temperature. Chemical and mechanical resistance depends on the number of coats of oil that are applied. The material dries with oxidation – please observe the general application instructions. Films or carpets must not be placed on the parquet flooring until it has completely hardened. Skin may form due to the high reactivity. Please remove before agitating. Subsequently the material should be filtered as a precaution. Stir carefully before use. Please observe the latest material safety data sheet!The coloured oil can be hardened 25 : 1 with OIL-HARDENER HIGH-SOLID OR 5180 before processing to provide additional protection against pigment abrasion for particularly heavily used surfaces . Or the coloured oil surface can again be finish treated with a clear oil. Our NATURAL-OIL OE 52832 can generally be used for this purpose. In the case of lighter colour tones, it is advisable to use PROTECT-OIL OE 52842 due to its light intrinsic colour and its excellent light fastness for an oil. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.