CREATIVE-METALLIC DB 4655x(gloss level)-(colour tone)

CREATIVE-METALLIC colour lacquer can be used to create unique pieces for interior fittings and on furniture and doors. Produce the most beautiful metallic effects with coarse to fine metallics, from silver, copper and gold colour tones through to modern, bright metallics. The associated CREATIVE-METALLIC colour chart displays 112 different colour tones that depict the full diversity of this system. All of the lacquers in this range can of course also be mixed with one another for a virtually limitless variety of effects.

Enquire articlePage content

- Application on wood materials and glass

- A colour chart with 112 colour tones is available for your customer conversations

Processing

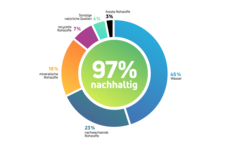

- water 1%

- renewable resources 9%

- mineral resources 16%

- fossil resources 74%

Areas of application

This fast-drying lacquer system has been developed especially for interior fittings and shop fitting. The coating of furniture and doors represents an additional benefit. The same lacquer can also be used for decorative glass coating on elements like glass doors, shower partitions and glass within furniture.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Number of layers (max) | 1 |

| Quantity per layers (min) | 80 g/m² |

| Quantity per layers (max) | 120 g/m² |

| Total quantity applied | 120 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: DR 4070 |

| Mixing ratio (gravimetric) | 100 : 10 | Hardener: DR 4070 |

Processing Instructions

| Potlife | 8 h / 20 °C |

|---|---|

| Drying | 16 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 150 - 320 |

| Intermediate sanding (grain size) | |

| Yield per pass | 9 m²/l |

| Processing information | A single layer application of 80 - 120 g/m² in the spraying process is recommended for CREATIVE-METALLIC DB 4655x(gloss level)-(colour tone). Formation of the effect and colour tone is largely dependent on the working method, application quantity and substrate condition. DB 4655x(gloss level)-(colour tone) should not be applied too wet to enable a uniform effect to be achieved. We therefore recommend the use of smaller nozzles (1.2 - 1.5 mm) when using a cup gun for application. The spray nozzle sizes specified under "Application" in this Technical Information are default values for Metallic lacquers. A trial coating should be performed as required!Use of Thinners: For smaller surface areas we recommend our PU Thinner DV 4900, and DV 4994 for larger surface areas. The quantity to be added to the lacquer/hardener mixture is around 10 - 40 % depending on the colour tone, effect and component.Use of alternative hardener: supplementary to hardening with PU Hardener DR 4070, it is also possible to use our PU Hardener DR 4071 in a mixing ratio (by volume) 10 : 1.Gold and copper colour tones: it is best to use lower coating thicknesses (50 - 70 g/m²) to obtain ideal brilliance when working with colour tones in the GD and CU series. Fine sanding and polishing of the substrate is advisable. Parallel surfaces with the "Sanded-Metallic" effect can be achieved on coarsely sanded substrates (80 - 180 grit). Please refer to the technical information on our homepage.Coating glass: coating glass cleaned using Cleaning thinner ZD 101 requires the use of our PU Hardener DR 4076-0001 in a mixing ratio (by volume) 5 : 1. The application quantity is 130 - 160 g/m². An application quantity of 80 - 120 g/m² is advisable when using gold and copper colour tones. The processing time for DB 4655x(gloss level)-(colour tone) when hardened using PU Hardener DR 4076-0001 is 5 - 6 h / 20 °C. Coated panes of glass can be glued after storing for 7 d / 20 °C.Coating on sheet steel or stainless metal: after careful degreasing using PU Thinner DV 4900 or DV 4994, then DB 4655x(gloss level)-(colour tone) in a mixing ratio (by volume) 5 : 1 with PU Hardener DR 4076-0001 can be used to coat sheet steel or stainless metal. Polishing of the steel sheet or metal surface additionally improves the adhesion of DB 4655x(gloss level)-(colour tone). The user should independently apply a test coat and finally approve it by means of a cross-cut test. Please feel free to contact your relevant Hesse sales representative in case of need. |

| Special notes | DB 4655x-(gloss level)-(colour tone) can be recoated with a transparent PU Lacquer to obtain optimised chemical and mechanical resistance and an individual gloss level. Please follow the instructions in the “Finishing” section of this Technical Information. Products from the same range can be mixed with one another. Depending on surface requirement and substrate material, it is possible to use our Isolating fillers including DP 4791-9343, DP 4755-9343 and DP 4788-9343 for pre-priming. The colour tones shown in the colour chart may deviate from the actual lacquering results. Various application methods and substrates are decisive in development of the effect. The colour tone may also appear somewhat different to that depicted when using clear top coats and when coating behind glass. It is therefore advisable to conduct a trial coating for inspection. We recommend using a soft duster for normal dry cleaning. Microfibre or leather cloths are suitable for damp cleaning. Dampen the cloth with water, wring it out and damp clean. Harsh household cleaners or abrasive substances are not suitable!In gloss levels x = 0, 1, 2, 3, 4, 5, this product is exclusively permitted to be combined with other approved and technically suitable products if it is to be used as a low-flammable coating for seagoing vessels in accordance with SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, latest version, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ.1120. The maximum application amount in wet film when this product is used as a low-flammable coating for seagoing vessels is 120 g/m². This does not apply to application onto glass and metal!“A risk assessment has been conducted in accordance with Directive 2014/90/EU, Annex II, Section 3. The hardened and dried coating poses neither a physical or health hazard nor a hazard to the environment.” |

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.