FANTASTIC-FILL DP 4755-9005

FANTASTIC-FILL DP 4755-9005 is an acrylate-based very full-bodied black and aromatic-free PU Isolating filler. Its application friendly thixotropy facilitates application on edges and vertical surfaces. After brief drying the rear can even be coated using FANTASTIC-FILL and the piece can then be stored in a tray trolley without any problems. FANTASTIC-FILL DP 4755-9005 has specifically been developed as a full-bodied, pigmented basecoat beneath dark Hesse PU Colour lacquers and additionally features process-oriented, powdered manual and machine sanding.

Enquire articlePage content

- excellent ability to stay on vertical surfaces

- fast drying and stacking strength

- outstanding manual and machine sanding

- process- and cost-oriented

Processing

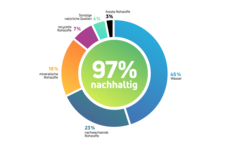

- renewable resources 1%

- mineral resources 48%

- fossil resources 51%

Areas of application

FANTASTC-FILL DP 4755-9005 can be used in all areas of interior design and shopfitting, including in kitchens, bathrooms and the fitting out of ship interiors. After sufficient substrate sanding, it can also be used without hesitation on the widest variety of woods, MDF and many laminates. Its excellent adhesion properties mean that this PU Isolating filler can additionally be used as an adhesion primer on various plastics.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 0,432 % |

|---|---|

| Appearance | opaque |

| VOC EU % | 37,6 % |

| Number of layers (max) | 3 |

| Quantity per layers (min) | 140 g/m² |

| Quantity per layers (max) | 300 g/m² |

| Total quantity applied | 550 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: DR 4071 |

| Mixing ratio (gravimetric) | 100 : 7 | Hardener: DR 4071 |

Processing Instructions

| Potlife | 6 h / 20 °C |

|---|---|

| Drying | 3 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Surface sanding (grain size) | 150 - 320 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 5 - 10 m²/l |

| Special notes | FANTASTIC-FILL can universally be used with the properties of an isolating filler in a mixing ratio (by volume) of 10 : 1 with PU Hardener DR 4071. In this hardening ratio FANTASTIC-FILL can in parallel be used on the following sanded metals from which grease has been removed: iron, galvanized iron, V2A sheet metals and aluminium. And additionally on ABS and PVC plastics after careful surface sanding and cleaning. Deviating metals and plastics will require testing. Conduct a trial coating as necessary. FANTASTIC-FILL is Decopaint-compliant in a mixing ratio (by volume) of 3 : 1 with PU Hardener DR 4076-0001 without the addition of thinner. It also meets the requirements of ChemVOC FarbV. On MDF substrates: Thick boards that have been created by gluing together several thinner boards are, due to the variance in tension, susceptible to edge ridging. It is better to select a single MDF board of the appropriate thickness. Panels that have been glued together should always be sanded flat at the edges and colourlessly pre-insulated. Any water introduced by gluing must be allowed to evaporate prior to coating.This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is 150 g/m².“A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.