PERFECT-FILL HDP 5650-(colour tone)

Our PERFECT-FILL HDP 5650-(colour) has been developed as the preferred system filler for combination with PERFECT-COLOR HDB 5434x(gloss level)-(colour tone). Its ease of processing and wide area of application, including its suitability for surfaces subject to heavy wear and in damp locations and the like, make it a universal filler throughout interiors. Flame retardant according to IMO and DIN EN 13501-1. PERFECT-FILL can be sanded by machine and can be recoated using all suitable Hesse lacquer systems.

Enquire articlePage content

- Good body

- Thixotropic

- IMO-approved

- flame retardant according to EN 13501-1

- as a system filler with the same hardener under PERFECT-COLOR

Processing

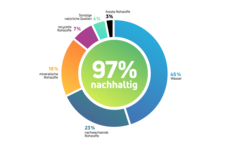

- water 36%

- mineral resources 39%

- fossil resources 25%

Areas of application

For all interior designs, ideal for heavily used surfaces such as in kitchens, bathrooms and offices. And throughout residential settings, for instance for tables and sideboards; on a wide selection of wood species, on plywood, MDF, and on the edges of MDF. Also for stairs and handrails.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Decopaint base | wb |

| Decopaint category | J |

| Number of layers (max) | 3 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 200 g/m² |

| Total quantity applied | 600 g/m² |

| Mixing ratio (volumetric) | 8 : 1 | Hardener: HDR 5091 |

| Mixing ratio (gravimetric) | 100 : 10 | Hardener: HDR 5091 |

Processing Instructions

| Potlife | 2 h / 20 °C |

|---|---|

| Drying | 5 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Surface sanding (grain size) | 120 - 400 |

| Intermediate sanding (grain size) | 280 - 400 |

| Yield per pass | 7 m²/l |

| Processing information | Add the hardener in a slow stream while stirring. Then add water as necessary to adjust the spray viscosity. Maximum added quantity 5 %. The hardener must always be added before dilution! Never store any material mixed with hardener in closed packaging.Subsequent coating: after sufficient drying and intermediate sanding, apply another coat of the same product or suitable HYDRO or PU materials as required. Use water to clean work tools. Use Hesse HYDRO Cleaning agent HV 6917 to remove any dried lacquer residues. Rinse out combined application devices (HYDRO and solvent lacquers) using Hesse HYDRO Reversing agent HV 6904.When directly coating cleaned or sanded foils, please apply a test coat to check the adhesion!Adding up to 5 % of PERFECT-COLOR Colour lacquer or our HYDRO Colour pastes can as necessary be used to tint PERFECT-FILL in pastel shades.Please note that this can impact the rheology, covering/filling power and sanding/polishing. |

| Special notes | This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is 150 g/m².“A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.