UNA-PUR DE 4259x(gloss level)

UNA-PUR DE 4259x(gloss level) is a light fast and transparent, acrylic-based Multicoat lacquer. Its versatile application options and uncomplicated processing make DE 4259x(gloss level) ideal as a multicoat lacquer on all common woods and at the same time an excellent finishing coat on Hesse PU Colour lacquers. It features very good adhesion properties, so DE 4259x(gloss level) can also be used on bleached woods in gloss levels from dull matt to glossy. DE 4259x(gloss level) was tested by the French CSTB and classified as non-flammable according to French Standard M1. The lacquer is equally low-flammable according to DIN 4102-B1.

UNA-PUR together with PU Hardener DR 4070-0070 has been tested for food contact and is accordingly passed as safe by a declaration of conformity.

Enquire articlePage content

- Declaration of conformity for food contact

- light fastness and can be used on bleached types of wood

- low-flammability according to German Industrial Standard 4102 B1

- low-flammability according to French standard; M1. Standard; M1

- suitable for glass coatings

Processing

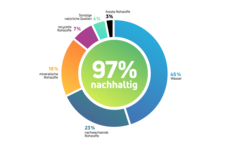

- water 1%

- renewable resources 1%

- mineral resources 2%

- fossil resources 96%

Areas of application

DE 4259x(gloss level) can be used for shopfitting and all interior fixtures and fittings, including in kitchens and bathrooms and the fitting out of ship interiors. In parallel DE 4259x(gloss level) can also be used in different hardening versions. Detailed information on this can be found under “Processing instructions” in this technical information.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | colourless |

|---|---|

| Number of layers (max) | 1 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 150 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: DR 4070 |

| Mixing ratio (gravimetric) | 100 : 10 | Hardener: DR 4070 |

Processing Instructions

| Potlife | 3 d / 20 °C |

|---|---|

| Drying | 2 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 150 - 180 |

| Intermediate sanding (grain size) | 280 - 320 |

| Yield per pass | m²/l |

| Processing information | The requirements relating to a declaration of conformity for contact with dry food and food containing free fat on the surface are exclusively achieved with UNA-PUR DE 4259x(gloss level) in the mixing ratio (by volume) 10 : 1 with DR 4070-0070. Hardening the lacquer/hardener mixture (by volume) at 5 : 1 with PU Hardener DR 4070 or 10 : 1 with PU Hardener DR 4071 is advisable for coating critical substrates or to optimise chemical and mechanical resistance.Hardening the lacquer/hardener mixture (by volume) at 5 : 1 with PU Hardener DR 4076-0001, after prior incorporation of 5 % Glass lacquer additive EL 460-0025 to the lacquer components, additionally enables direct coating onto glass. It is necessary to properly clean the glass surface to be lacquered beforehand using Cleaning thinner ZD 101. |

| Special notes | This product can only be combined with other approved and technically suitable products when used as a flame-retardant coating for seagoing vessels in accordance with SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when used as a flame retardant coating material for seagoing vessels is 150 g/m².The dull matt configuration of DE 42590 and the extra matt formulation of DE 42590-0007 (please observe the separate technical information) may not be used as a multicoat lacquer, but only as a 1-coat finish! Hesse UNA-PUR DE 4259x(gloss level) is ideally suited as a finishing coat on Hesse UNA-COLOR DB 4524x(gloss level)-(colour tone) and provides outstanding metal-marking resistance. Hesse UNA-COLOR DB 4524x(gloss level)-(colour tone) can be used to tint Hesse UNA-PUR DE 4259x(gloss level). Pre-priming is possible depending on surface requirements and substrate, for instance using Hesse Basecoats DG 4741, DG 4734, DG 4717-0004, DG 4768-0004 and DG 4763. “A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.