Equipment planning

Use our expertise!

A parquet flooring customer in Austria *) who changed his production process from traditional oiling to Oxi-reactive oiling noted the costs incurred very precisely. In his calculation he worked out what production costs he could save by switching over. He took staffing, materials, transport and equipment costs into account.

The bottom line showed he achieved a 40.8 % reduction in overall costs!

Effective gain in space

by eliminating trolleys

Effective gain in space

by eliminating trolleys

The space saved by eliminating trolleys for drying is immense! Make effective use of this saved space for other things.

Another parquet flooring manufacturer *) eliminated his trolleys and stacks. He now uses the space previously taken up by the drying parquet flooring for a new packing system and as preparation area for despatch.

*)does not wish to be named on the website

Are UV oils really natural?

There are alternatives to UV oil

Are UV oils really natural?

There are alternatives to UV oil

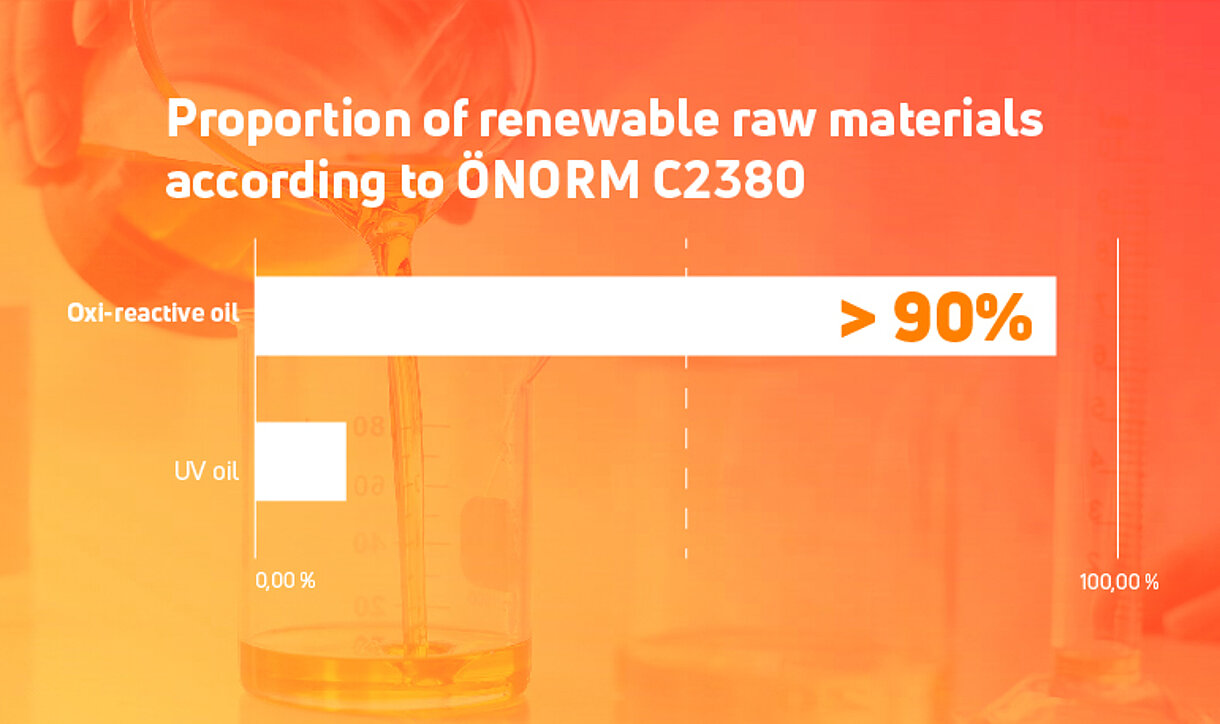

The word “oil” sounds sustainable. UV-oils are quick, but sadly often not as sustainable as the name leads you to believe.

Here is a broad insight into the ingredients - only relative to the ratio of natural or renewable raw materials.

To have a discussion on this topic with an expert, contact our responsible Product Manager Ralf Untiedt directly. He is a specialist in the parquet flooring industry and has looked in detail at the formulations, properties and degree of sustainability of various different oils.

Modular system

Just a few lacquers for many programmes!

Imagine if you could reduced the overall number of your lacquers by 30 %. You would have fewer surface products in use, and yet you would be able to satisfy your sales and your customers with all the programmes they wished for. That would reduce your stock-holding and eliminate much of the time your staff spend moving around.

But clearly, with fewer lacquers the greatest potential saving for you lies in the reduced setup times. Let’s assume in an ideal world you only use one basecoat and 2 top coats for six different programmes, instead of 6 base coats and 6 top coats as you did previously. The benefits are obvious.

We worked out just such an individual modular system for the parquet flooring manufacturer Hamberger, and this has now been successfully implemented.

Energy costs too high?

Water-based lacquer drying v. UV lacquer:

Energy costs too high?

Water-based lacquer drying v. UV lacquer:

In an internal study, the CO² footprint of various lacquer systems were compared, taking application and drying into account.

Based on the data collected, energy consumption for lacquer drying and hardening can be determined. If coating with a water-based lacquer and subsequent drying in a hot-air dryer are compared with that of a rolled UV surface, significant savings ensue.

Using the UV lacquer means energy savings of more than 90 % can be achieved!

Your challenges?

Individual solutions are our strength